Industrial Inspection Camera Systems

Innovative and Individual – Our Solutions for your Particular Inspection

viZaar News

https://vizaar.de/wp-content/uploads/2023/04/Vuman-E3-News-EN.jpg

483

601

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2023-04-28 08:25:002023-04-28 11:31:54The One and Only VUMAN E3 – Part 2

https://vizaar.de/wp-content/uploads/2023/04/Vuman-E3-News-EN.jpg

483

601

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2023-04-28 08:25:002023-04-28 11:31:54The One and Only VUMAN E3 – Part 2 https://vizaar.de/wp-content/uploads/2023/02/Standort-Deutschland_600x483_EN.jpg

483

600

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2023-02-08 15:40:402023-02-08 17:14:01viZaar North Germany

https://vizaar.de/wp-content/uploads/2023/02/Standort-Deutschland_600x483_EN.jpg

483

600

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2023-02-08 15:40:402023-02-08 17:14:01viZaar North Germany https://vizaar.de/wp-content/uploads/2022/11/VUMAN-E3-the-original.jpg

483

601

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

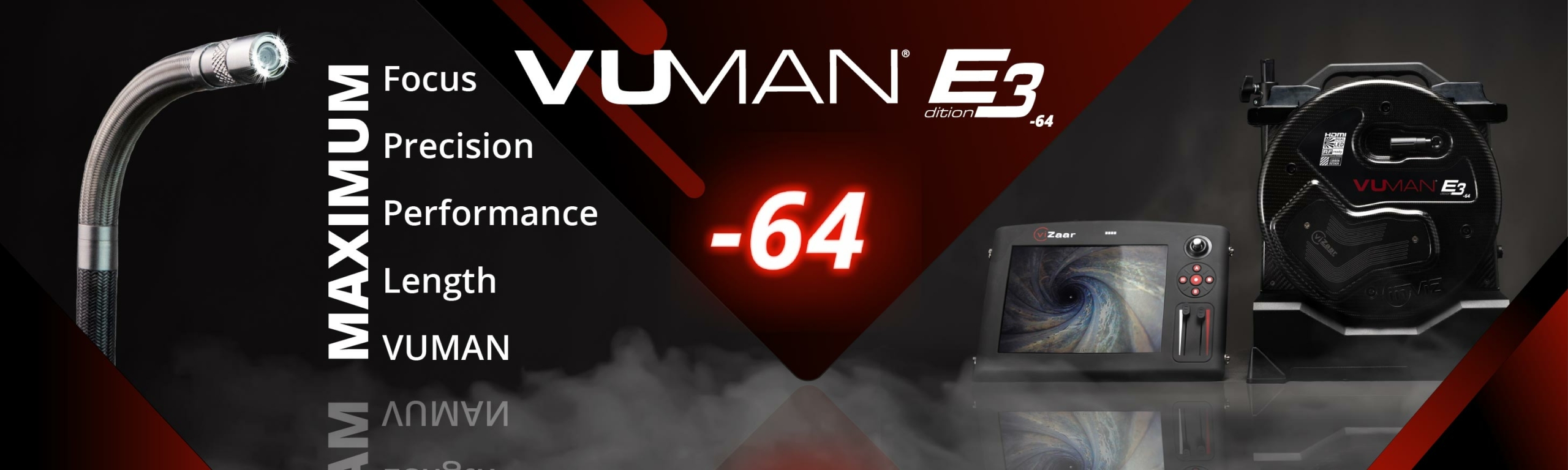

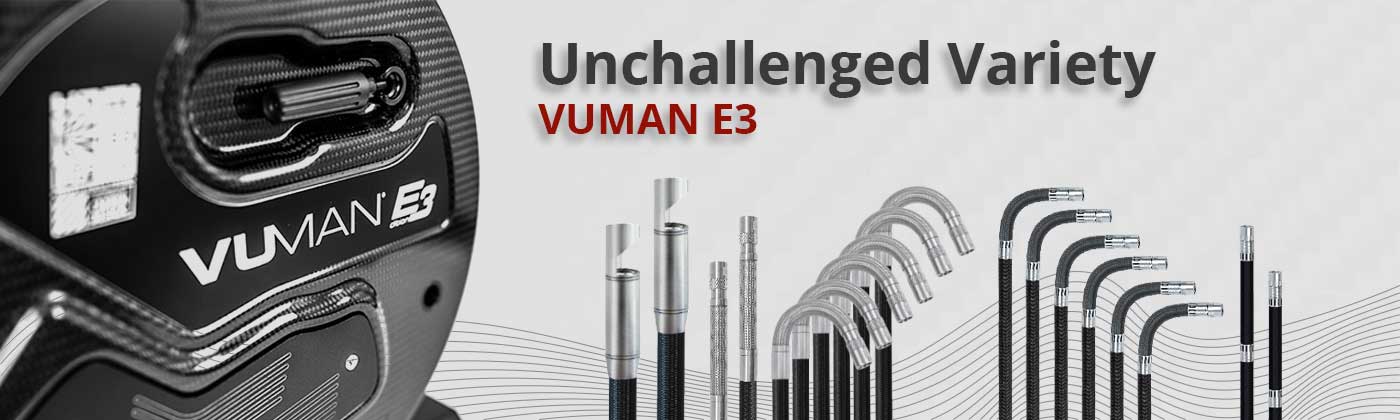

Denice Zaar2022-11-11 16:36:112022-11-11 16:37:11VUMAN E3 – The Original in 3D

https://vizaar.de/wp-content/uploads/2022/11/VUMAN-E3-the-original.jpg

483

601

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-11-11 16:36:112022-11-11 16:37:11VUMAN E3 – The Original in 3D https://vizaar.de/wp-content/uploads/2022/09/viZaar-Achema-22-15.jpg

1359

1453

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-09-05 08:35:532022-09-05 08:39:17Achema 2022

https://vizaar.de/wp-content/uploads/2022/09/viZaar-Achema-22-15.jpg

1359

1453

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-09-05 08:35:532022-09-05 08:39:17Achema 2022 https://vizaar.de/wp-content/uploads/2022/07/Elios-3_Bild-6.jpg

800

1200

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-07-05 12:19:402022-07-05 12:19:46Elios 3 Roadshow in Weilmünster

https://vizaar.de/wp-content/uploads/2022/07/Elios-3_Bild-6.jpg

800

1200

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-07-05 12:19:402022-07-05 12:19:46Elios 3 Roadshow in Weilmünster https://vizaar.de/wp-content/uploads/2022/05/Control22_viZaar-29.jpg

1200

801

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-05-17 09:18:122022-05-17 09:18:15Control 2022

https://vizaar.de/wp-content/uploads/2022/05/Control22_viZaar-29.jpg

1200

801

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2022-05-17 09:18:122022-05-17 09:18:15Control 2022 https://vizaar.de/wp-content/uploads/2020/07/SNK-60x-Kamerakopf.jpg

600

600

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2020-06-09 16:01:022020-07-29 11:05:31SNK 60x – As mobile as never before

https://vizaar.de/wp-content/uploads/2020/07/SNK-60x-Kamerakopf.jpg

600

600

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2020-06-09 16:01:022020-07-29 11:05:31SNK 60x – As mobile as never before https://vizaar.de/wp-content/uploads/2020/07/VUCAM-4-mm-66m.jpg

470

891

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2020-04-25 16:28:382020-10-13 11:30:27VUCAM 4 mm with 6.6 m length!

https://vizaar.de/wp-content/uploads/2020/07/VUCAM-4-mm-66m.jpg

470

891

Denice Zaar

https://vizaar.de/wp-content/uploads/2024/09/viZaar-industrial-imaging-AG-xpandingyourvu-Illustrator.png

Denice Zaar2020-04-25 16:28:382020-10-13 11:30:27VUCAM 4 mm with 6.6 m length!Contact us!

We are here for you!

If you have any questions regarding our products or NDT services or if you need competent advice and support with your remote visual inspection, don’t hesitate to contact us!

Further contact information

viZaar industrial imaging AG

Hechinger Straße 152

72461 Albstadt | GERMANY

Fon.: +49 7432 98375-0

Fax: +49 7432 98375-50

E-Mail: info@vizaar.com